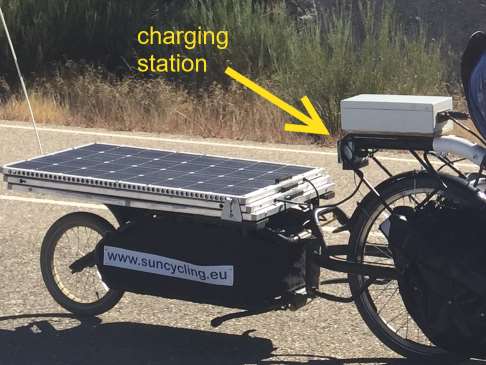

charging station

After a day of cycling (and navigating) both my power bank and phone need to be recharged. Expecting to camp 'in the wild' without wall sockets I made my own charging station. This station enables me to charge all my mobile devices from the cycling battery and leave a bunch of wall adapters at home. The fact that the charging station is fixed to the bicycle has another advantage: I will not be able to forget the charger at the campsite.

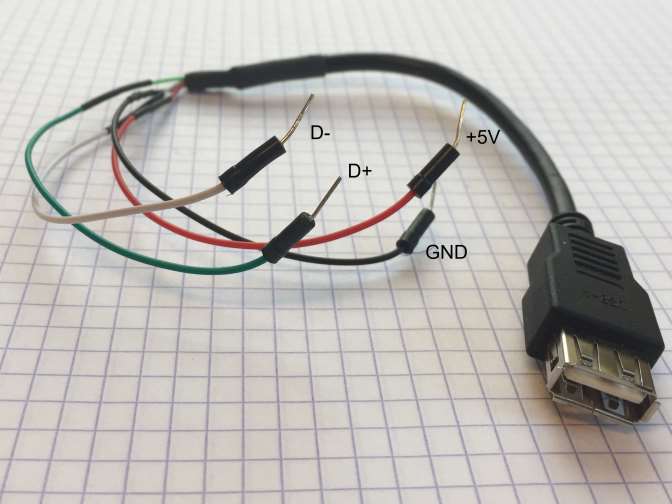

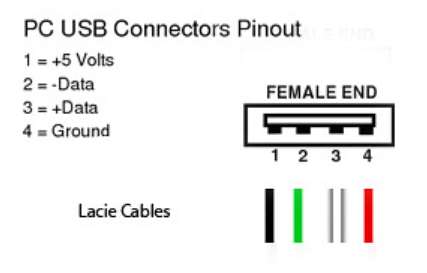

The energy needed for the charging station is only a very small portion (<1%) of the total energy consumption of the motor. My iPhone can be charged from a USB socket at 5V. So all that I would need is an efficient DC/DC converter that can supply a sufficient amount of power to a female USB socket. Such a socket can be obtained by cutting up a USB extension cable, or buying one from electronics parts supplier like Conrad, Farnell etc.

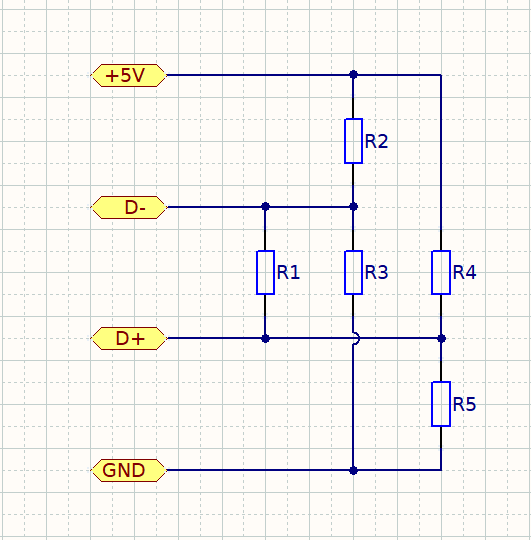

Connect the GND (GROUND) and +5V to the output of the DC\DC converter. But there is more to it. Sophisticated devices like mobile phones may have to 'recognise' the charger before they will allow sufficient current to flow. This recognition is done over the remaining two datalines (+D,-D) . The internationally approved USB standard states that when thes lines are simply shorted together the device should start charging up to a maximum of 1,5 Amps. This amount of current would charge any mobile phone in less than an hour !

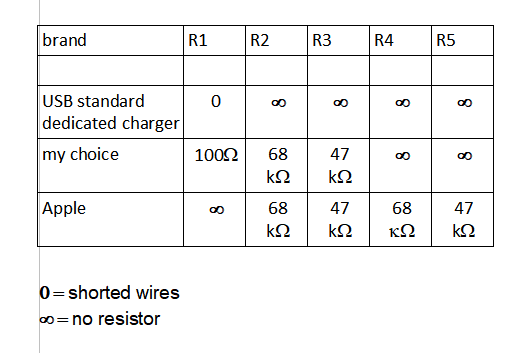

Unfortunatly big brands like Apple decided to not follow the standard and introduce their own electrical signature. This would allow them to let chargers from other brands function poorly. My iPhone6 even gives off a warning "this accesory may not be supported" when a Sony USB charger is used. Fortunately the signature of the original charger is fairly simple to emulate with a few resistors:

Laptop charging

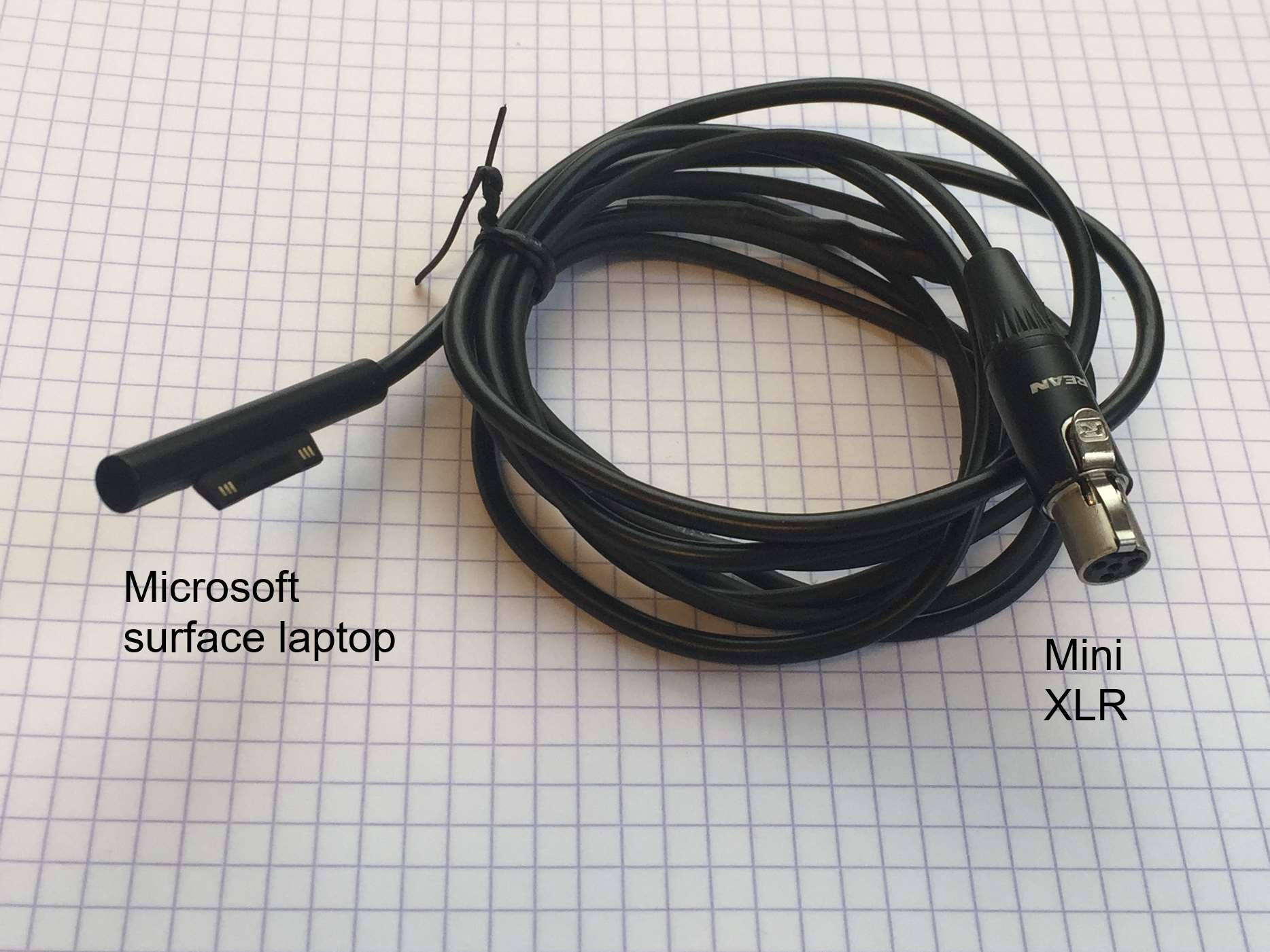

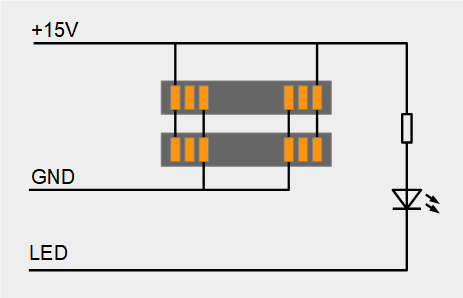

Charging my Microsoft Surface laptop presented another problem. The connector Microsoft Surface cannot be bought separately so I had to buy one and cut the cable just to get hold of this connector. The connector has the shape of spade and is held in place on the laptop with magnets. On both side of the spade there are 6 contacts:

There is also a LED inside the connector which shows the user that the charger is working. This LED is controlled by the charger through a separate line. I did not connect this line.

On the other side of the cable I used a 3-pole mini XLR connnector.

DC/DC converter

If you only need to charge a mobile phone +5V / 0.5A (2.5W) will be sufficient. Most laptops will need higher voltage (i.e 14V, 18V etc.) , so for this you would need a second DC/DC converter. One that I can recommend here is the i3A brick module from TDK. It is very compact and can convert an incredible 100W of power. You set the voltage using just one resistor. Further information in the datasheet of this product: https://www.emea.lambda.tdk.com/de/products/product-details.aspx?scid=394

fuse

Although you may have a main fuse at your battery it is recommended to have lower value to the charging station of 1A or 2A. There are many different types of fuses. I chose to use the automotive ATO type because it is widely available at petrol stations and garages.

opinion

If all manufacturers would adopt a single standardised power supply / charger (which is essentially the same thing) we would not end up with so many different power adaptors in our homes and in our garbage! When you forget to take along your charger and run out of power you can just borrow one from a collegue, a friend or a hotellier which will always fit. Doesn't matter whether it's a an Samsung, Apple, or Huaway. This is another example of a win-win situation for consumers and also for the environment because the production of electronic products is very dirty business and has a large CO2 footprint (says the electronics developer!). The only ones that do not benefit are big corporations that want outsmart their competition and let us pay the maximum for their overpriced products.