battery-assembly

Johan recommended to increase the size of my battery and I was glad I listened to him. There were those days that the sun just did not appear and I wanted to escape from places where I did not want to be; like overcrowded campings. At such moments that extra energy is very welcome.

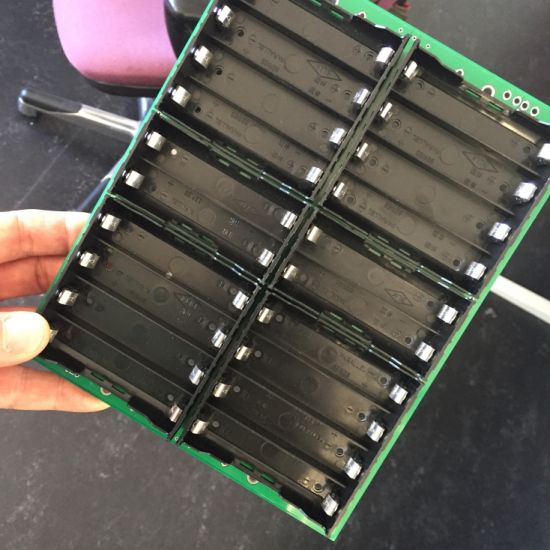

My battery is made up of a 100 type 18650 cells. The 18650 cells format is the most common on the market and are used for laptops, bicycles and even cars. 10 cells in parallel and 10 of these banks in series. Such a configuration is sometimes called 10p10s.

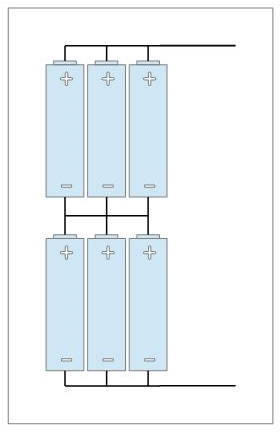

Example 3p2s:

A charged Lithium battery contains a lot of energy as we experienced when one cell was accidentally shorted. The high current works like a welding machine . The cell then takes off like Chinese fireworks. Imagine what could happen if the energy of a 100 cells would go off. Dangerous.. well yes, but petrol tank of a car is also potentially dangerous.

To make it as safe as possible I put the assembly into a stainless steel box with a metal lid that is loose. The batteries are soldered onto a pcb (printed circuit board) using battery cell holders. Using holders the cells can be replaced if necessary giving the assembly a second life. Each cell has a 3A fuse. If a cell suddenly becomes a short, which can happen in very rare cases, the fuse will blow without harming the other cells.

Overcharging Lithium cells can cause permanent damage. There is always a difference in cell capacity even in new cells from the same manufacturing batch. So as one bank is still taking charge the other bank in series could be full and get overcharged which is very damaging to lithium cells.

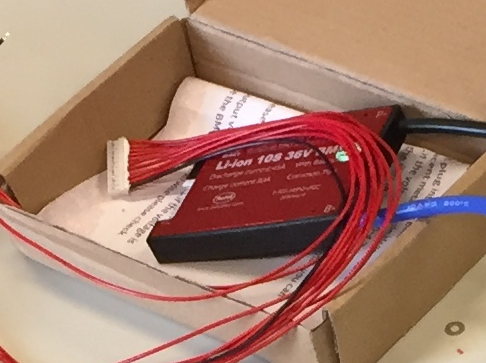

When you assemble your own battery you care should be taken to use batteries that are very closely matched in capacity. The best way to assure this is to use new cells from the same production batch. A Battery Management System (BMS) can correct small differences in cell capacity. It actually bypasses these cells with a small current. The BMS also protects against undercharge and short circuits. It is an important part of the battery.

BMS, brand Daly / AliExpress

Note : A standard BMS will only correct in the order milliAmps while the charging current is in te order of Amps. So this will only help when the cells are almost equal. Big dfferences in cell capacity, when different recycled cells are mixed, cannot be corrected by a standard BMS !

Johan recommends when you use recycled cells with standard BMS only charging a cell to a voltage of 4.1V instead of the specified max. voltage of 4.2V per cell. He noticed that number of charging cycles can be increased dramatically by simply lowering this charging voltage. Normal number of cycles is 1000x but by lowering the voltage it can easily go up to 2000x.

Of course the manufacturers of battery packs will not come up with such ideas for prolonging the lifetime of the cells.